Interview with America’s water reuse expert BioprocessH20 on challenges and the future of water

An interview with BioprocessH20 Tim Burns, company CEO, entrepreneuring wastewater treatment for the Food and Beverage industry

Water is the most extensively used raw material in the food and beverage industry. It is used for processing, as an additive to products, but also as a cleaning agent. But waste can’t just go down the drain.

Due to heavy loads of chemicals and biological waste, industrially processed water needs to be filtered before it goes to the municipal water treatment center. The industrial sector can have an impact on the environment and economy as a result of rising water demand and wastewater production. In some US states aquifers have run dry. With the increasing scarcity of drinking water, the reuse of wastewater has become an important economic and ecological concern. Optimizing water consumption and wastewater reuse in the food industry is necessary for business reasons and a growing list of environmental ones enforced by governments.

Food processors, industrial manufacturers, automobile manufacturers, oil and gas companies and more all need to be mindful of the wastewater they produce when they conduct their core business.

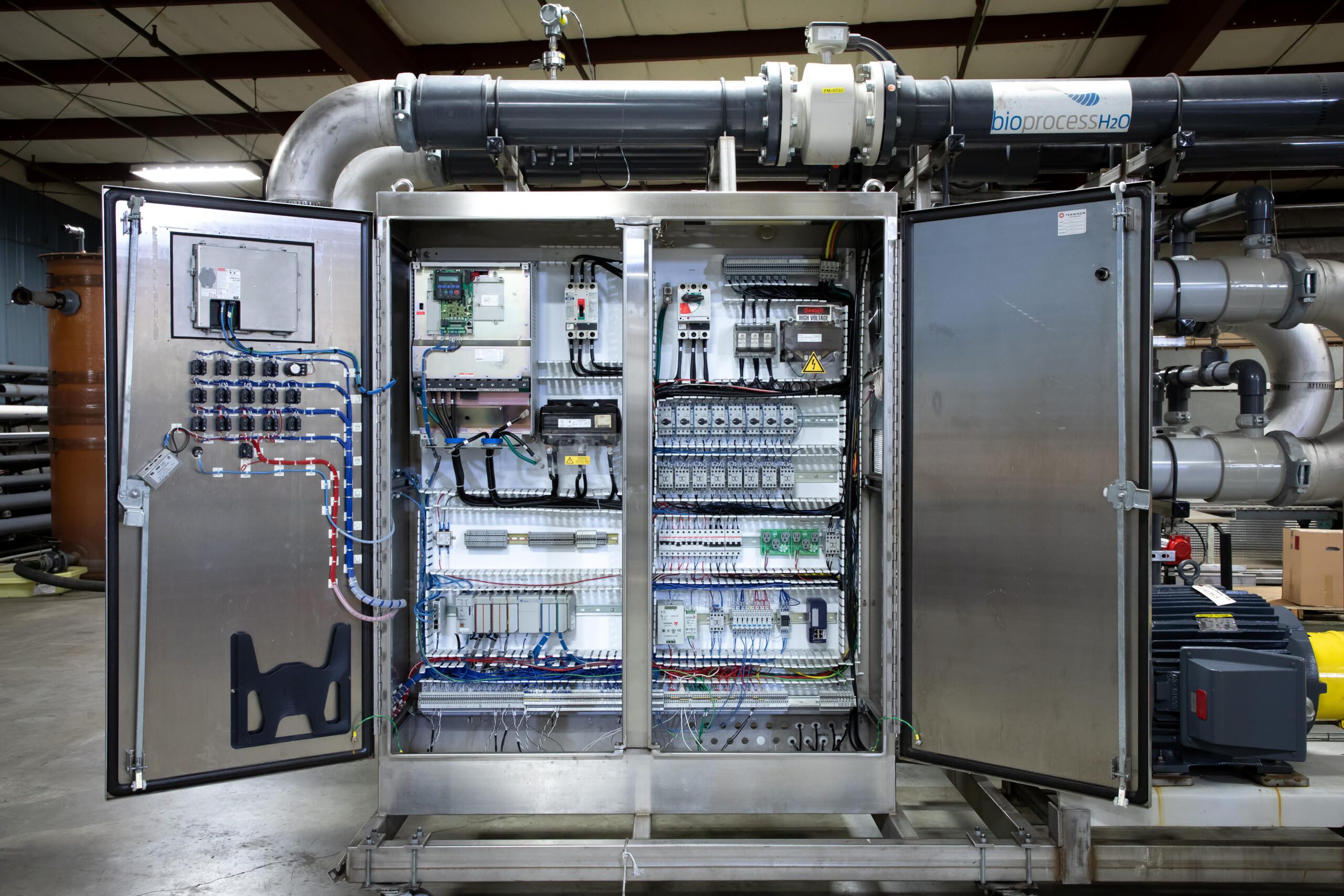

All forms of waste, whether liquid or solid, require specialized treatment methods before disposal. Where do companies turn? What does the future look like? We speak with the world leader in sustainable wastewater treatment, BioprocessH2O, an American company from Rhode Island that mimics nature in their system designs. Clients like Coca Cola use their system to meet wastewater standards in the food industry.

Tim Burns

Tim Burns, the CEO of BioprocessH2O shares some insight into a global challenge of wastewater treatment and its potential for reuse.

Give us an overview of why companies turn to you.

Companies turn to us for our expertise in the wastewater field. We have some of the best engineers in the business, and are confident in the systems that we build. We have helped some of the biggest companies in the US get control over their wastewater, and because of that many turn into repeat customers.

Are there non-US locations you work with and what special challenges do you face outside the US?

We work with companies across the world, with a focus in North America. Each country has its own unique regulating body, that has its own set of parameters or rules that they adhere to. This makes it different from the US, as not all regulators are concerned with the same things.

When you work with non-US companies, let’s say EU, Canada and the Middle East. If you work there, or want to work there, how are the standards and demands different?

The testing standards, and goals, are different in many of the countries you mentioned. For example, in the Middle East we recognize that the biggest water related questions are around desalination and water reuse, to help the countries there that do not get much rainfall get more access to water. This is different from the US, Canada and the EU that has ample rainfall, ands main concern tends to environmental and public health harm reduction.

Working with Coca Cola

What do you love most about your job?

I love that we get to solve hard challenges for our clients, while helping the environment and public health.

What frontline technologies is your company looking at? If you could invent a time machine, what would the future look like for your business in 20 years?

We actually are now a preferred partner for Zwitterco which has developed a new membrane that has promising lab results, and we hope this translates into promising installations for our clients. The Zwitterco membranes use a certain type of material which has both a negative and positive charge, this in effect reduces the amount of membrane fouling expected in a membrane system.

To the second part of the question, I think that in 20 years from now, we will be a lot better about testing, and pinpointing sources of wastewater than we are today. If we could have a “magic” technology, it would be one type of filtration method that worked for all types of pollutants.

What research centers around the world are doing the best work in wastewater remediation?

That is a good question. I would say the best research still comes out of universities. For example, the Reverse Osmosis, and the new membranes I have talked about previously, both came out of partnerships with labs from universities. This is very common across industries, not just ours. You see this in tech, as well as biotech and pharma.

How do things get trickier in areas where aquifers are depleted, like in California, or let’s say in Saudi Arabia?

We expect people in this region to be more concerned with water use reduction, instead of just water filtration. As water becomes more scarce, it becomes more expensive, leading to higher input water costs for manufacturing plants.

Could you work with agriculture solutions that use treated greywater? If yes, how. Hydroponics, aquaponics, greenhouse ag or conventional farming.

Yes this is common in our industry, where a farm will need to filter their wastewater, and then are actually able to use the filtered water to water their crops of something of this nature. While wastewater filtered by our systems are not always drinkable, it is often clean enough to use for other purposes.

What does a company need to do today to ensure they can scale their water treatment solutions so they will be relevant in 15 years?

A lot of the time it comes down to planning ahead. We work with our clients to understand their production goals now, and in the future, to figure out the size of the water system that needs to be installed in order to handle and plant expansions that may be in the future.

Now how can we ensure that we scale? I think we just need to stick to our plan, which is to give our customers the best systems we can at a fair price. This allows us to show our competence, and has helped grow our name in the wastewater industry.

Give us a bit about your background.

I have had a very entrepreneurial career. I left the corporate world early on, and helped scale a chemical disposal company working with the founders. From there I founded a few companies, one of which was bioprocessAlgae, which aimed to turn Algae into biofuel. I have a finance/business background and took up a masters in environmental science from Brown University.

Comments

creditSource link